Machining is the means by which we shape and cut materials to produce a variety of parts and products. If we’re not smart about the materials during this process, we can make a lot of garbage. At Shanghai Ruimin Moldplastic Technology, we strive for improved machining so less material is used, which is good for the environment.

How Machining Affects Waste

The very first part of the reduction of machining waste is understanding how different cutting will give us more or less waste. We might, for instance, cut too long or hard or quickly, and take off more material out of the waste. And by picking the right cutting settings how fast and how much material to take away at one time we can generate less waste and make better use of materials.

Intelligent Cuts That Save The Best Cuts.

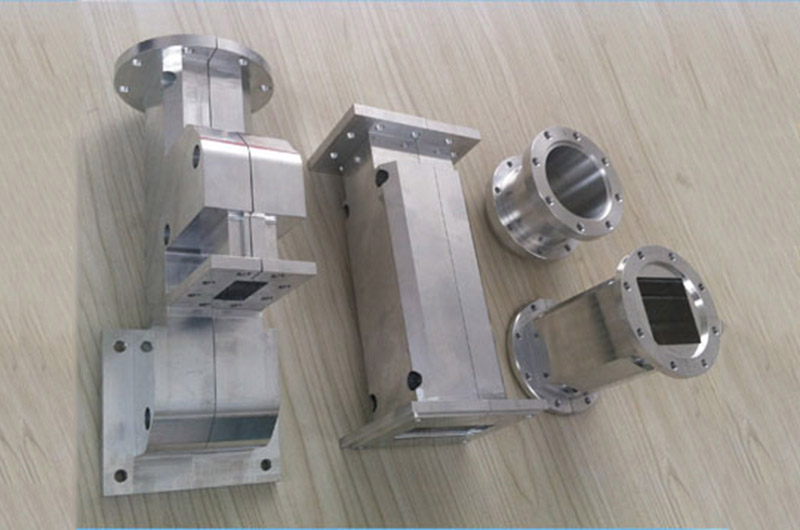

Smart Metal Parts Machining cutting strategies is one way to reduce waste. That is, using the best tools and the best methods for the job, and making sure that we cut as precisely as we can. Since we can use the sharpest cutting tools high-speed steel or carbide inserts we can waste less material. And if we change up our slicing speeds and methods, there are other ways to achieve smoother surfaces with fewer extra steps that may end up consuming more material.

Advanced Equipment and Tools Utilized

If you need to do some machining as cost-effectively as possible and to waste as little as possible, we can use the most cutting edge of tools and techniques. For instance, CNC Machining Service allows us to manage cutting parameters very exactly, resulting in less material used and less waste generated. And we can plan and optimize machining processes before we start, with the help of special software, to enable us to find options to minimize waste.

Following the Tracks to Waste Reductions

One other part of making machining better is paying attention to data on our work. And by observing things like cutting force, how tools wear and how much material we remove, we discover ways to make less waste and better our work. Studying this data helps us see where waste is occurring and to find ways to trim it, like adjusting our cutting settings or attempting new techniques.

Collaborating to Better Utilize Materials

Finally, suppling and partner collaborations are essential for using materials in a better and highly effective way in machining. By working with our suppliers to source higher quality materials that waste less, we can become more lean and green. Also, working with other companies helps us exchange ideas and learn from each other about waste reduction and drives improvements in our machining methods.

To sum up, it’s crucial to make CNC Machining better and also help eliminating waste… both regarding being efficient and regarding the environment. By understanding why machining makes waste, with smart cutting strategies, advanced tools and technology, data tracking and the cooperation of partners, we can use less of it and make our work better. At Shanghai Ruimin Moldplastic Technology, we are commited to optimize our machining to waste less and create a better future for our industry and our planet.