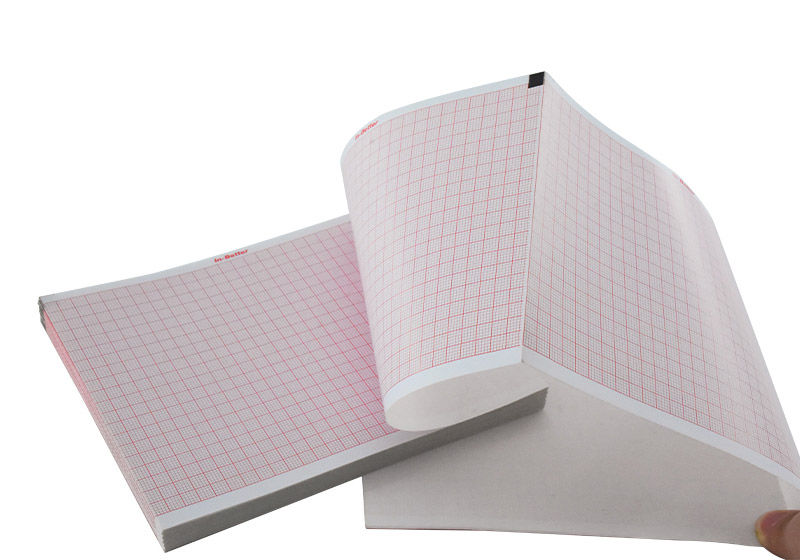

Supplier audits are very essential to ensure that the ECG paper that we use is of high quality. In-better, which supplies medical products, knows how important it is to work with good factories that have strict quality control systems in place. In this article, we will discuss the major QC rules for a quality testing of factories producing ECG paper.

Why the ECG Paper Production Suppliers Evaluation is Important

It’s also about checking whether the factories we work with have the right processes to make ECG paper.” By conducting regular audits, we can identify and address any issues early onworking with the factory to rectify them. This is what helps us maintain high level quality in the ECG paper we supply to our customers.

Critical Quality Control Criteria for ECG Paper Factory

When we evaluate a factory on producing ECG paper, we see several important aspects. These considerations including the extent to which the factory adheres to quality control rules, to safety regulations, has the capacity to finish goods in a timely manner, are always innovating and have a history of cranking out high-quality products.

Adherence to rules and standards in the manufacture of ECG paper

Manufacturers should adhere to safety guidelines to manufacture ECG Medical Paper. In other words, they have to use the right kinds of materials, follow the right steps in making the paper, and test what results at the end. By ensuring they adhere to these rules, we can have confidence knowing that the ECG paper we provide is safe, and of a good standard.

Establishing Good Relationship with ECG Paper Suppliers

Through conducting reliable audits and cooperating sincerely with our ecg paper suppliers, a good long-term partnership between our partners can be established. That allows us to speak honestly about any issues, and work together to resolve them. If we get better among our suppliers, then we can increase the quality of the ECG paper we sold and make it with our good relationship with our clients.

Quality(None) with Factory Inspections to get better quality and reliablity.

Strict factory inspections plays a very good part to assure the quality and reliability of the ecg paper we supply. It allows us to investigate the production process for any potential issues, or for any areas where we can improve. This enables us to collaborate with manufacturer in order to implement changes that can enhance the quality and reliability of the ECG paper. "By growing steadily through strict inspections, we are able to maintain high quality in the products delivered.

Conclusion

ConclusionSupplier audits are an essential component of ensuring the quality of the ECG paper we provide. By adhering to the important quality control rules, complying with the safety regulations, establishing good relationship with suppliers and carrying out due diligence on factories, we can make the ECG paper we supply of higher quality and more reliable. In-better is committed to offering high-quality products to our customers, but we also believe good service is our duty.