There are key things to remember when you use an air compressor that runs on a diesel engine to ensure everyone’s safety. One of the things is you want good ventilation. For ventilating out harmful fumes or gases left from the air compressor running. That’s critical because these fumes can ignite and blow up if they’re not vented properly.

The electrical aspects of the air compressor should also be regularly inspected. Electrical parts Cummins explosion Proof Diesel Engines can spark and ignite a fire when they aren’t in good working order. You can check for loose wires or broken parts to help make sure everything is safe.

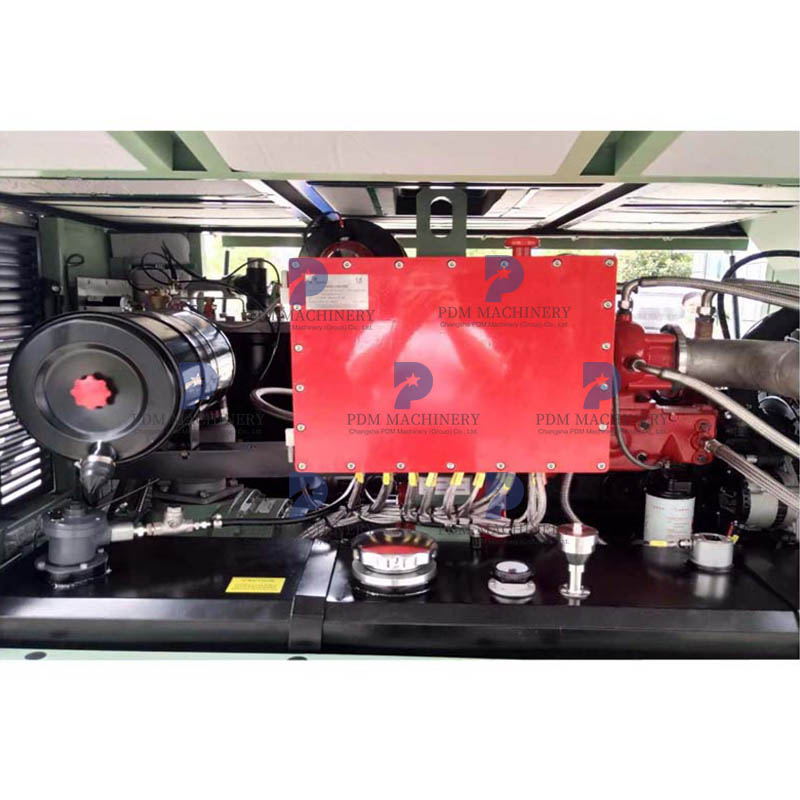

Another consideration to have is preventing heat or sparks from getting near the air compressor. This Explosion Proof Diesel Engine Power Generator Set includes no open flames in the vicinity. Additionally, you’ll need to be careful storing flammable materials and treating them. Keep these materials in a secure place where nothing can catch it on fire. If they are stored correctly, it can prevent fires or explosions.

Inspection of safety device is very important to use diesel engine air compressor. Safety features such as pressure relief valves and emergency shutdown systems will need to be shown to work effectively. These products prevent all too common, dangerous fuel spills that can lead to explosion. If you check these safety devices on a regular basis, you can help maintain the air compressor safely.

To sum up, the operation of Explosion Proof Diesel Engine Air Compressor Unit, we should pay attention to some safety operation, avoid explosion, etc. You can help avoid accidents by knowing your need for good ventilation, keeping electrical components in good repair, controlling ignition sources, keeping flammable substances stored in a safe location and checking safety devices regularly. And of course, when we’re dealing with machines like air compressors, safety is always the most crucial consideration. Never forget safety rules to keep yourself and others safe from harm.