Our mining equipment can work for long time. This can render the devices inefficient and raise issues. Fortunately, there’s a remedy for this hard tungsten steel components!

Why You Should Choose Wear Resistant Parts For Your Mining Machinery

The wear-resisting parts are the most key weared parts for the mining machinery equipment, also mine machine is not exception the wear-resisting part mainly comes from the presence or long-term friction impact, surface lip rubbing on, grinding or hitting shell surface scraping loss. Without these components, the machines would wear out far more quickly, leading to frequent repairs and replacements. For mining companies, this can be expensive and time consuming. With wear-resistant parts, mining machinery can accomplish this and last longer and perform better.

Ways Tungsten Steel Parts Make Mining Equipment Last Longer

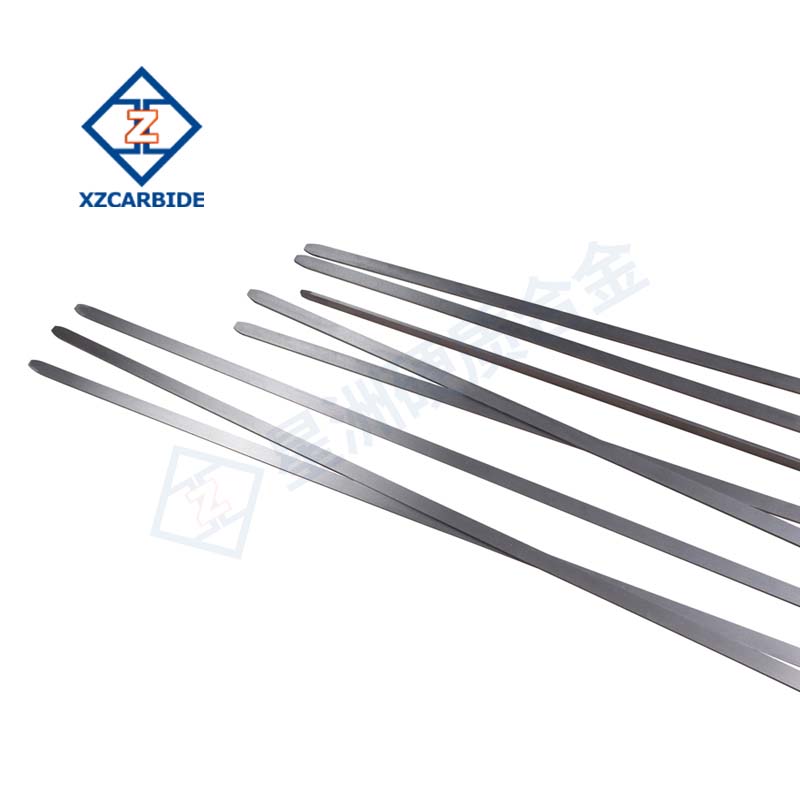

Tungsten steel is a hard, tough material, wear resistance, not easy to break. In other words, for drill or tungsten steel, the use of tungsten steel parts can make the machine usable for a longer period of time than the usual. That means mining companies can save on costs for repairs and replacements, as well as have less downtime when the machines are not working. With the purchase of high quality wear parts, mining businesses can ensure that their machines are in top working condition for years.

The Advantages of Applying Tungsten Steel in Mining Machinery

There are several advantages of Tungsten steel blade for stainless steel in mining machinery. For one thing, it doesn’t wear as readily, meaning the machines last longer. Tungsten steel components are also very sturdy and durable, meaning they are ideal for use within the harsh conditions of mining work. And tungsten steel is immune to rust, so it can possibly make mining equipment even sturdier. Through using tungsten steel parts in their machines, mining companies are able to work more efficiently and more rapidly.

Extending the Life Cycle of Your Mining Equipment

It’s really important to minimize wear and tear on machines in mining work. One of the best methods in which this can be achieved is through the uses of wear resistant parts in the machines for example, one can use tungsten steel. These parts can extend the life of the machines by minimizing damage from rubbing and scratching. Preventative evaluation and maintenance are also key to finding problems early and fixing them before they become major problems.

Enhance Overall Performance in Mining Equipment It’s not all about the power when it comes to mining equipment performance.

Companies can make their machines work better by using Tungsten steel wear-resistant partss in mining equipment. Using tungsten steel parts may eventually reduce downtime and maintenance costs by extending the life of the equipment. It can also increase the throughput for mining operations and make more money. Making an investment in high quality wear parts can often be one of the things that allow mining companies to succeed and ensure that their facilities are kept running smoothly.